Big Time.

No jury of her peers would convict her.

I couldn’t help myself.

I should have known better than to be cruising Craig’s List at 2:00 AM on a Saturday night.

But it was an offer I couldn’t resist.

New they are running anywhere from $2500 to $3500 depending on where you look.

For just the machine.

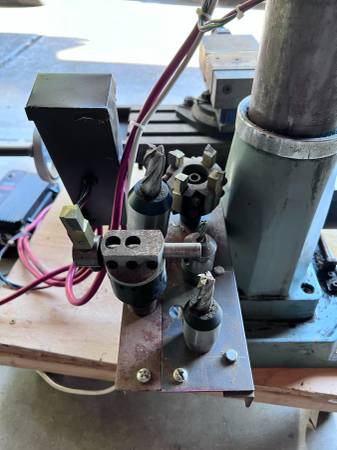

I got that, with an upgrade to a brand new 12V motor and controller system that is adjustable for speed, a machinist’s vise plus several milling attachments and a couple of add on lights, for $900.

Easily a $1,000 worth of extras.

The thing is in excellent condition too.

The Wifely Unit is furious.

Mainly because I sprang it on her at the last minute but just for General Purposes because I am spending money too.

It took quite a while and the help of a good friend to get it out of the back of the truck, onto a big metal work table and then back into the garage but it’s in there just waiting.

It has the R8 collet system and I even have a set of those out there already.

The guy was an engineer apparently and had passed away, his nephew is a lawyer and came up from Oakland CA to clean up his estate and said flat out that he knew it was probably worth a lot more than what he was asking for it but he had no use for it and it needed to go away.

So now it’s out in my garage and I can’t hardly get to it to use it.

I gotta get rid of some stuff man.

DUDE ! I still am running the machine I bought back in 1980 like that one.

has a smaller table, and takes Morse 3 tooling. but damn.

big time score there. and I still have the stock motor on mine too.

the ones I looked at where anywhere from 600 to a grand to do the motor setup

you have there.

found the paperwork on my machine. a Jet -15, price 995 plus tax

of course. came with a okay face mill and a drill press type of vise

Oct. 1980

and mine does not have the table stops they put in later ones.

still, it has been a good machine for me.

had a chance to pick up a Bridgeport for cheap years ago.

just didn’t have the space for it , or a way to move it either !

and the one time I saw a nice Rockwell mill for sale, I didn’t have the funds to get it.

It’s easier to ask forgiveness than to beg for permission.

I think I saw that on a fortune cookie, once.

Bingo, and it’s got its very own CCW switch, what caliber?

Whatever gets the job done and hasn’t been lost in a tragic canoeing accident.

JL, isn’t that in the Bible?

Could be. I stopped reading at “an eye for an eye and a tooth for a tooth”. Leviticus, if memory serves me right…

Nice score!

Enjoy sleeping on the coach,it is worth it!

$900 fishnagles. Are you going to make money with it i hope? My supposed better half shit a brick when i spent $1500 on a new chainsaw while its put many times that amount in the coffers since. For me its in one ear and out the other most days sad to say.

You struck GOLD there.

I agree that asking forgiveness is easier than asking permission.

Ask me how I know that…

It is on WHEELS.

It followed you home.

Right fellas? I seen it myself.

You put it back three times. And it still followed you home.

Buy her a popsicle and tell her to STFU.

Kewl! I want one! I’d have to move to have have a place to set it up. But still…

Sure would like to find some machine tools. And some time to use them would be nice as well.

You need bigger pictures embedded; I can’t tell a thing about it; who made it, what model and all that. It looks big, and I know an R8 spindle is usually on more capable machines. My Grizzly G0704 has that.

How many HP (or watts) is the motor? How big is it? Table size? How many RPMs does the motor do? What’s the Z-axis height? That sort of stuff.

I think it could be in the same size class as my Grizzly. Today, the G0704 is $2300 plus shipping, which is about $1000 more than when I got mine.

Can’t even find a build plate or a sticker identifying the manufacturer yet!

Looks to me like a Rong Fu 45 clone, similar to “Grizzly G0705 – 8″ x 29″ 2 HP Mill/Drill with Stand” https://www.grizzly.com/products/grizzly-8-x-29-2-hp-mill-drill-with-stand/g0705

Well, you have always been open about being a tool junkie, but this is the icing and strawberries on the cake for your latest, umm, acquisition.

chuckling

Heck of a buy. Gotta convince the wife you are upgrading and sell off some of the lesser used stuff. I just scored a 1964 Mercedes Benz fintail body, for 150 bucks. Can sell the speedometer instrument head alone for 3 times that.

Am stripping all the parts I need to fix the one in the barn, then it goes to scrapyard,. wife actually did not put up resistance last week.

On a very sad note, my brother in law went home not feeling well this am and literally passed away like a switch was turned. Dealing with all the fallout now, not a good way to start the week, God give us all strength.

Oh man, that is terrible news.

My condolences Bud may God give everyone the strength to deal with this tragedy.

Prayers up POD

Sorry to hear that, Terrapod.

May he rest in peace and your family find solace soon.

Leigh

Whitehall, NY

What a deal! Good for ya, Phil!

If you can use it to do jobs that bring in money then do so. The wifey can’t complain about tools that produce income.

I love it. The “Wifely Unit”. Sounds like some artificial intelligence concoction.

On the flip side, I shudder to think of who’s going sell my shit after I die. No one in my family has any idea of the value and someone out there is going get some hellacious bargains. My son, who likes fishing, can’t tell the difference between a $50 Walmart special rod and reel and a $500 custom built rod and reel. Jeez. Hope whoever gets it enjoys it.

My biggest fear is my wife selling my stuff for what I told her it cost.

Unashamedly stolen from somewhere……

BUT

It is the absolute truth.

Leigh

Whitehall, NY

You have a floor in your garage?

I had to build a 10×22 lean on the garage to find mine, and now a 40′ container to make the garage usable again.

The homestead will be defended to the death because I ain’t moving anymore, as I now have room for all my shit and the wife surf FB for more useful stuff…

braver man than me!

She also can’t complain about a special gift you make for her that could only have been made on that machine.

Phil, with all the machinist gear you got going, I’m waiting on the new and improved busted nuckles version of the liberator.

https://en.m.wikipedia.org/wiki/FP-45_Liberator

well, something like that is handy to finish a 80% lower.

or maybe some more advance projects, like rebuilding a PPsH 41

parts kits are like under 400 bucks now.

or any other “parts kits” you may find for sale.

I remember passing up on Sten kits for 50 bucks back in the 1990’s

UZI’s where like 99 bucks or so. looking back on it. I really wish I had grabbed a few of them at the gun shows back then.

Back in the 90’s, the Joy Store was selling Norinco AK’s and SKS’s for less than $100. Back then, who wanted that commie garbage.

If we had only known.

🙁

Leigh

Whitehall, NY

Here’s how to take care of the W Unit. Develop a small product that you can sell on Ebay. Tell the Unit that the money you make goes into her account. Back in the 90’s, I spent probably 50 grand on tools and tooling. Told the wife that…someday this will make us money, if we wanted to do so, and that the money would be hers. Update to 2013, and I developed some products, sold them on Ebay, and grossed, over 5 years, about 250K part time…gave all the money to the wife.

She began asking me if I needed any more tools for the shop…I kid you not.

Genius!

I don’t want to hurt y’all’s sensitivities, but I was “sportin’0 wood as this was read.

SCORE!!! Only thing better than that would be a genuine Bridgeport Mill, but they usually have a 3-Phase Motor, and Weigh a Lot.

A cheap VFD takes care of the 3 phase issue. They are quite heavy. I need to move mine from my father’s garage to my shop. Don’t look forward to it.

Leigh

Whitehall, NY

A basic Bridgeport (1.5hp/2.0hp) weighs about 2400 lbs.

I wrapped a heavy towing strap around the centered turret slide ends, and picked it up with the winch/boom of a conventional towtruck. (the single cable winch is rated a minimum of 3500 lbs)

Run the knee all the way down, and rotate the milling head until it touches the padded table top. Move the truck slow, don’t let the mill swing around. Move the winch and/or boom up and down slowly. You can push it farther into the garage/shop using the wheel lift, once it is sitting on the concrete.

Don’t transport it hanging on the cable, that is just to get it moved to and from the car rated trailer. You want a minimum of FOUR heavy duty 2 inch ratchet straps to the top of the turret to stabilize it for transport.

Do NOT let the mill drop or tip over. Severe damage can result.

Also, the turret in not strongly mounted to the body, which is why you want to be gentle while it is lifted off the floor.

If moving it locally, you can hire a towtruck with auto trailer to handle the entire move. If not local, you will have to hire a truck at both ends, plus a vehicle to tow the trailer. Don’t bother trying to use a box truck or trailer, they usually don’t have enough door height to fit the mill with boom. Not all liftgates on box trucks have enough weight capacity to handle the mill, plus you still have to slide it into and out of the truck. Not worth the hassle, normally.

Don’t leave the mill head upside down too long, as all the grease and oils and swarf will fall onto the belts, and make a mess. Especially bad on the variable speed models.

It’s really top heavy with the motor/head in it’s normal orientation, which is why the factory recommends swinging the head down for transport.

If you have a forklift, it can be lifted with the forks under each end of the ram slide. Put a piece of lumber on each fork to protect the slide. Watch for tilt, you don’t want to have it slide off while moving it around.

Okay, Phil, I am now oficially saying I have a present for you. It will go well with your latest find. CederQ and i discussed it, I’ll be sending it to you Real Soon Now.

You forced my hand, you lucky devil, you!

Shit, my girl would be delighted that I got it so cheap!

After all these years, I get a picture of your house. Kitchen 10 x 10, LR 10 x 10, Bathroom 8 x 8, BR 12 x 12, garage 100x 100.

Was the guy’s name Charley S? Retired navy warrant machinist/mmcm

Never did hear the departed gentleman’s name, his nephew’s name is Jim.