D’OH!!

I don’t know if it was my eyes or my failing memory.

Because ya know, it’s just too easy to take a picture, right?

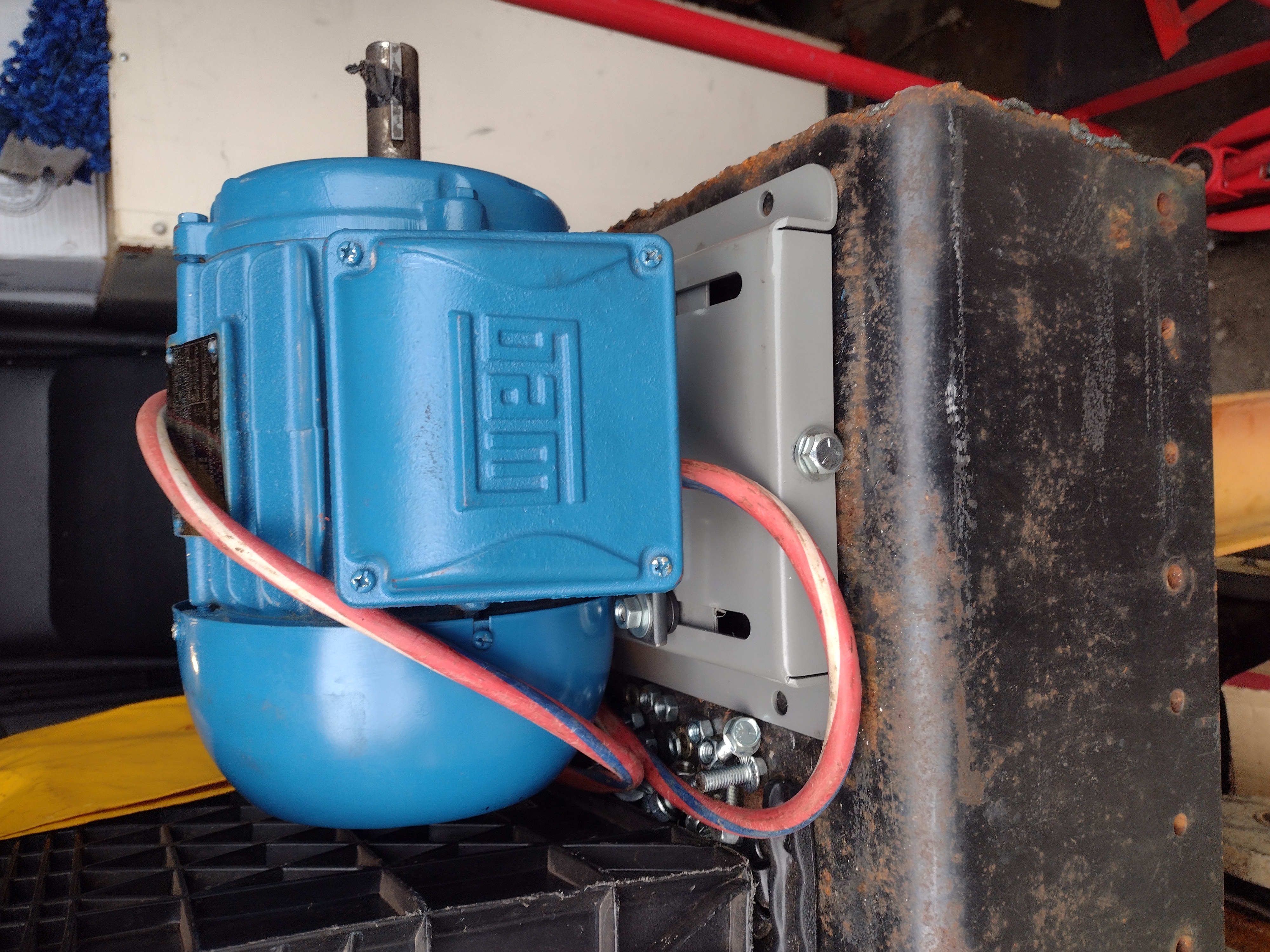

Like this maybe?

After busting my ass all day, I came home and tried to take a nap but no dice.

The NFL Draft is going and The Wifely Unit and The Kid are jumping up and down and yelling like the fucking house is on fire.

So out in the garage I went.

I was trying to see what kind of contortionist bending I am going to have to do to mount fender brackets on that little trailer when the skies opened up and it started pouring. So I scurried back inside for cover and passed that 220 Volt motor some very generous readers gave me a while back that needs to be mounted on my Smithy 3 In 1 lathe combo.

You know, the one that has been bugging the shit out of me every time I see it.

For the last three months or so.

Then I remembered that the adjustable bracket I had ordered for this little project had come in.

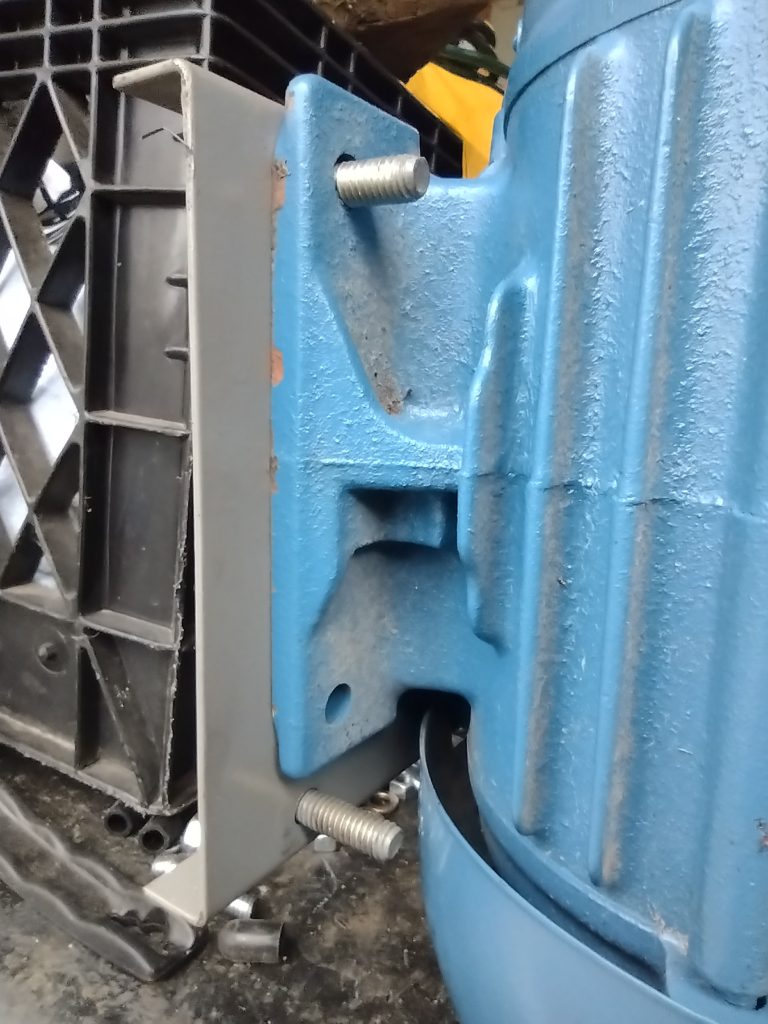

A little digging and pretty quick I am sticking the studs into the holes on the motor when I discovered the issue above.

WTF I muttered to myself.

So I take a closer look.

Again I mutter to myself,

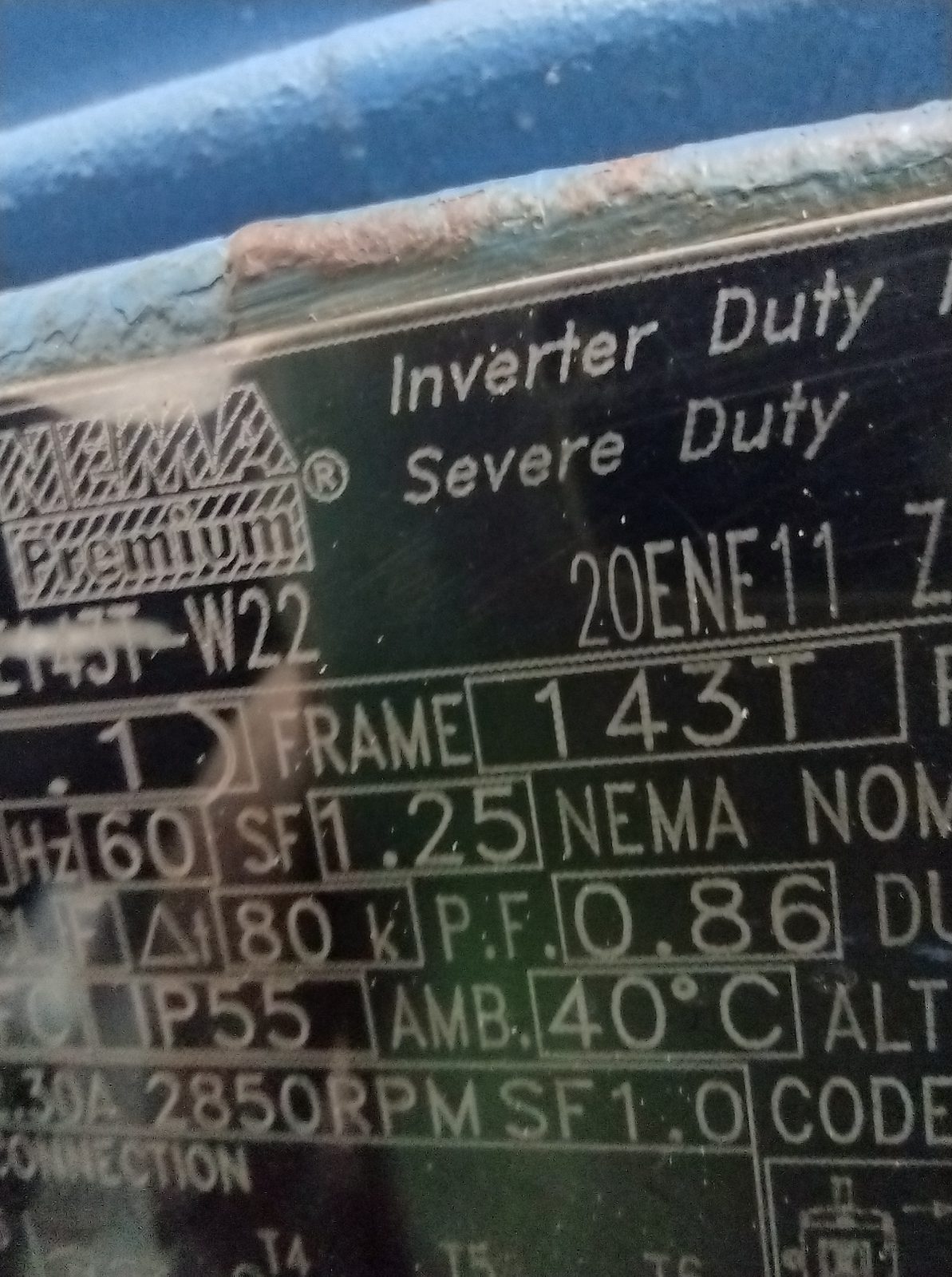

I needed a bracket for a 143T motor frame.

What did I order?

Son, ofabitch.

Now I has choices.

Two of the four holes actually line up.

I can either reorder the fucking thing, at $45 or I can get creative.

Yeah, you get one guess.

You guessed right.

There are a couple of really thick washers underneath to even it out and let it clamp more evenly and tighter.

It’s not going anywhere.

One step closer.

There is still a long way to go yet and I have a full plate this weekend yet again.

By the time I got done playing with that, including the brief rest after work, I just put in another 11 hour day.

I got up at 5 and came in the house at 7.

I busted ass today at work too, wrestling with some big ass iron pieces, 4 of us trying to put this huge expanding cone thing back together.

Think giant drill chuck but it expands instead of closing up.

Each section of the thing is basically like wrestling an engine block standing on end.

All 4 pieces have to come together at the exact same time, slowly walking them back and forth on the floor until they are all right next to each other and a center section with dovetails all around it has to slide down inside each piece at exactly the same time.

They have to be tilted back to get the dovetails started and have I mentioned they are really fucking heavy?

4 guys wrestling the bastards and another one running the crane to drop the center piece in.

Needless to say the thing is wore the fuck out and it took several tries to get it back together.

Now tomorrow we get to mount the heavy bastard on a six inch shaft sticking out of a giant gear box and then lift that whole thing up, set it down in a pit on a sliding table mount and then laser align a big electric motor to it.

Loads of fun.

At least it’s Friday tomorrow.

We shall see how much energy I have left after I get home from that.

The list is still very long and I have an absolute shit ton of things to do Saturday.

No rest for the wicked eh?

How many wimmin could wrangle that expanding cone thing? Equality…sure!

First thing I did when I saw the first pic was to check which website I was on. Thought maybe I hit FailArmy instead of bustednuckles!! I knew it was a motor from the casing but wasn’t sure of the hp. HOWEVER, I knew whatever size it was, that plastic crate he was trying to mount it to wasn’t going to hold it!! Then I scrolled a little further. Good laugh for a Friday morning. Thanks and have a good one!!

Like I always say no matter how simple the project, “Nothing is simple.”

Everyone has something that’s simple to them and magic to someone else.

Like this guy who tears down automatic transmissions and explains how things work and ways to improve them. He says “Pretty simple, really” a lot.

https://youtu.be/3P58KXKaFoE

Phil, I would have welded a lottls “spot” (or bump) to fit inside that clamp arm so that it can’t rotate out and slip. Only takes a second or two of stick time, and you can rest easy that it won’t walk out due to vibration.

Yes, I had the same idea you did, and as soon as I scrolled down, I was proud of you. Nuttin’ like African Engineering to make it work!

lottls = little

PIMF (Preview Is My Friend)

What’s a mill for if not to cut a new slot?

Yeah, Phil, being single, I’m having trouble imagining how it is that the only real breadwinner in your house isn’t allowed by other family members to get the sleep he needs, especially as he operates machinery that is not forgiving of tired workers. But as I say, it is your house. BTW, it’s amazing how critical electrical circuits inside noisy TVs or hi-fis can work their way loose when dad will need to make a deposit in the sleep bank.

Older equipment had a black plastic fuseholder knob on the outside, which you could remove with a quarter-turn.