I randomly ran across these while surfing Zuckerberg’s Cyber Stalking Site.

I thought they were pretty cool and immediately thought of my buddy Irish.

Then the more I looked, the more I liked so I bought one for myself!

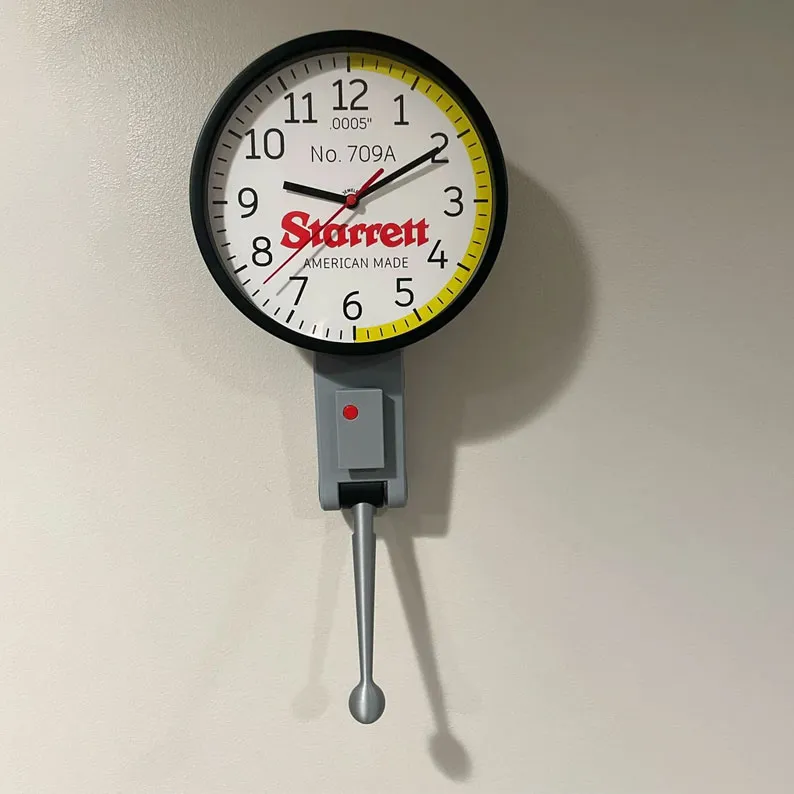

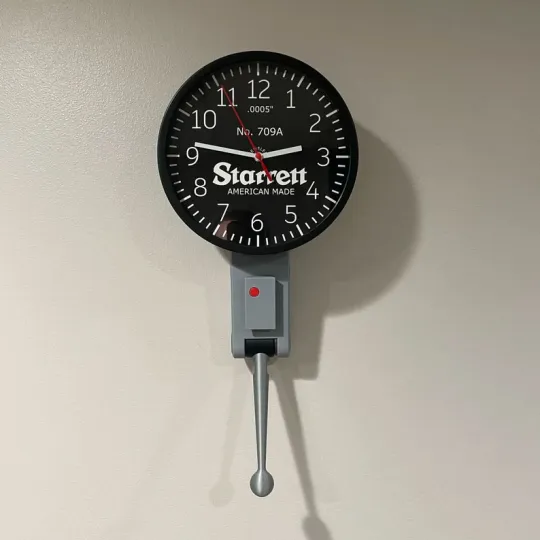

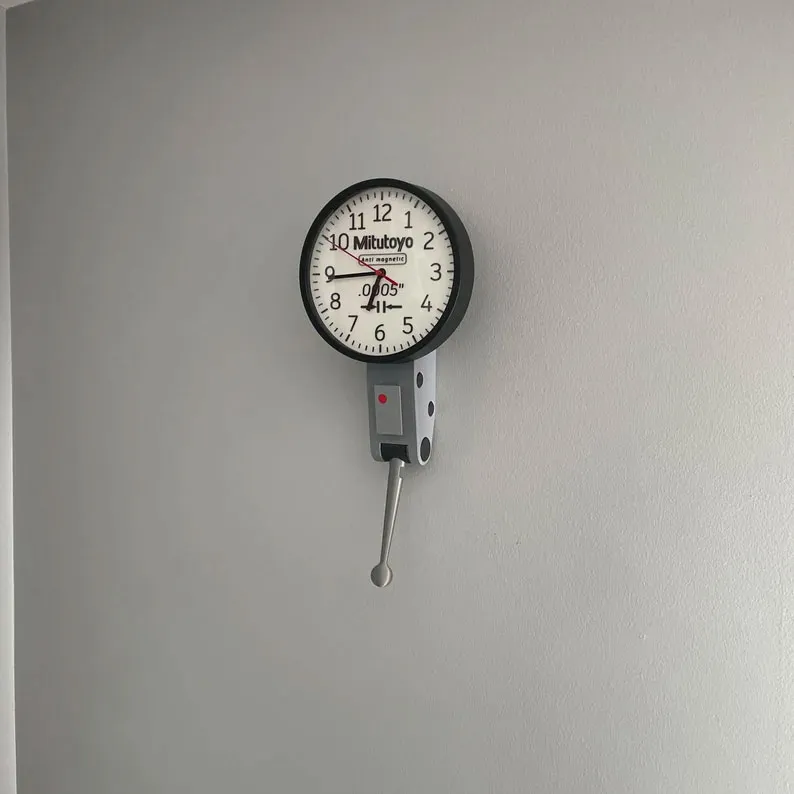

They offer several different brand names and styles.

The best part is that they aren’t wicked expensive either, just under $50, delivered.

8″ Dial Indicator Wall Clock, Great Gift for Machinist / Engineer / CNC Manufacturing Technician

Do they have a Brown and Sharpe, Best Test in 0 – 4 – 0 ?

Some of us still work in tenths.

😉

Leigh

Whitehall, NY

Middle right.

https://www.chriess.com/products/8-dial-indicator-wall-clock-great-gift-for-machinist-engineer-cnc-manufacturing-technician?campaign_id=120206564812640407&adset_id=120206564812730407&ad_id=120206564812840407&utm_medium=paid&utm_source=fb&utm_id=120206564812640407&utm_content=120206564812840407&utm_term=120206564812730407&utm_campaign=120206564812640407

If you click on the original link in the post you can look at all they have to offer,

Suddenly I feel a need to know what time it is in the shop. Thanks.

Love it. Many years of using these performing QA testing.

The probe arm should move in and out like a pendulum.

It’s a clock with a dong. Why would this be note-worthy?

↑↑↑↑

How to spot the non-mechanical dood.

I was going to say something like that. In the world we live in the population of people that “get” this is becoming limited.

We took a HS field trip to Athol MA and visited the Starrett plant as part of our Industrial Arts & Mechanical class. Very cool.

Now I’m going to have to check my Dad’s machinist tool chest. I know I’ve got one or more Starrett items from his home shop days. Neat idea.

Thanks, but I don’t want to know what time it is when I’m working a project. I stop when I’m hungry or cross-eyed.

Being an old single guy does have its benefits!

I believe we have peaked. The ability to recreate items built 30, 50, or 70 years ago is beyond our manufacturing capability.

The machine shop at the facility I work at is being converted to nearly all CNC. The new guys can tale a piece of steel and create nearly anything from scratch. If they have the G Code created from the engineering drawing. You have to find the guys near retirement if you want the simplest tasks performed manually. Something as simple as milling a bearing cap or cleaning up a keyway becomes a huge technical challenge. Spent some time at Johnson Space Centerin Houston. The guy giving the tour remarked that it was impossible to replicate the Saturn-V while standing in front of one.

Electronics technicians used to be able to perform component level troubleshooting and repair. Now it is rare to find anyone with the skills to do so.

Engineers used to be able to design and build things. Now they simply manage purchases of what they need.

We haven’t advanced our skills, we have simply replaced them.

This is going to bite civilization as a whole right in the ass.

Yes, I believe you are correct. Age, retirements, and death are steadily removing skilled folks from the workforce.

Boss commented that we needed to work toward training the newer folks to the level of the couple of old guys that they depend on to keep things running. He got a funny look on his face when I told him that if i started today, we would have someone with my level of skill and experience in about 40 years.

Apparently I am expected to cram 40 years of training, experience observation, trial and error, and learning from my (sometimes) dumbass mistakes into a two day training session.

Yeah, good luck with that.

I can’t afford their stuff. Is there a Chineseum model?