It could be that way for a couple more days too.

Yesterday was way worse than today and today was bad enough.

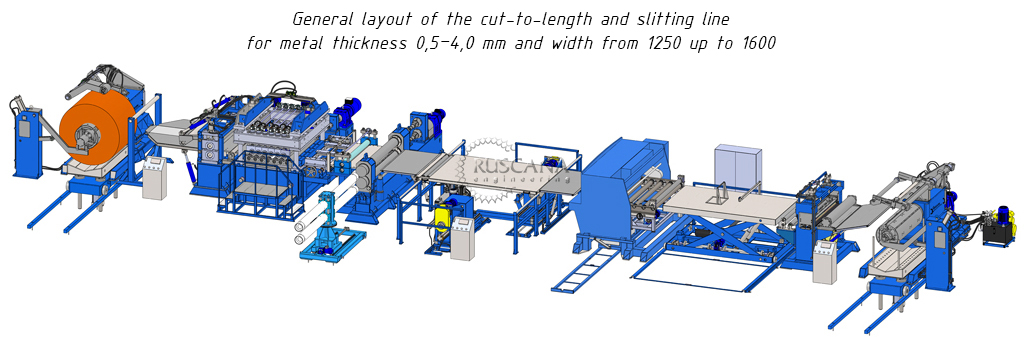

For those not familiar with what it is I work on and around now, let me give you a crash course.

You have probably seen a large roll of steel strapped down to the bed of a Big Rig Trailer before.

There is a huge machine where I work that takes that, unrolls it, flattens it out into a long sheet of plate steel and the cuts it to whatever length the customer wants.

Up to 1/2 inch thick steel.

It is actually called a Cut To Length machine.

Did I mention it’s rather large?

One of those rolls can weigh up to 50,000 pounds. Which is why you will generally only see one single roll on a truck bed.

There is a short rail spur that goes inside the warehouse and they roll rail cars inside that have 4 rolls on them and then unload them with an overhead crane, then stacks them up to wait their turn. We also get them by truck.

So if you take a closer look at the picture above, just to the right of the roll that is Orange colored, is what is called the Large Leveler.

This is a representative picture and not the actual one at work.

The top half of that box weighs 66,000 pounds.

There are two layers of hardened shafts, basically rolling pins, that squeeze the steel flat using hydraulic pressure as it rolls through the line.

Close to a millions pounds per square inch.

I don’t even remember how many huge bearings are inside bit it’s something like 200.

We are tearing that apart and rebuilding it. Us and some guys from the manufacturer.,

We have been short handed because a bunch of people are on vacation, just for fun.

This is a first for me.

Anyway, this thing is just naaaaasty. There is grease everywhere and it is thick and dirty.

I had to wash my hands and arms 3 times yesterday just so I could take a piss and it was a ten minute job each time. When I got home, I walked in the house, turned and went out to the garage, took my T shirt off and threw it in the garbage. There was no saving that sonofabitch.

The shower was a God send.

Because this kind of thing isn’t a barrel of monkeys all by it’s self, we got blasted with a heat wave yesterday.

It was 108 degrees outside when I got home yesterday and it was about 103 today.

All this while dealing with all the medical issues I have been experiencing.

Like drilling out broken 3/4 inch bolts, sideways, a foot off the ground, while kneeling on concrete today.

I am tired, sore and sweating my balls off even with the A/C going.

I am very grateful that CederQ has been picking up the slack because I am working this project and it is supposed to last until Friday at the very least.

If I last that long.

I bet that big bastard would resize your dinky little .223 brass pretty easily, Phil. Run them through a small base die, they’ll chamber fine in either the AR or the Mini-14.

Where I work we call the machine a blanker. 16 ton rolls cut into blanks for the multi-stage AA press. Whole side of car inner unibody.

So in other words he got the leash removed and there’s no oversight. You do realize it’s times like these when his twisted sadistic side posts things that torture us. We all know that you’re hurtin and it is hot too. But don’t be slacking off, get that thing back together and take back control of your blog before it becomes a complete clown show.

Your the head clown…

I thought I was, BFYTW

Hang in there Phil, and I do hope they are giving you hazardous duty pay along with overtime.

Back when I was doing longshoreman work we use to unload those from ship holes, steel slabs too. Some of the slabs weighed 40 tons. Don’t miss those days.

Damn, Phil… I hope they pay an honorable rate. Don’t kill yourself doing that shit. Just remember- the graveyard’s full of heros.

That’s a really beautiful machine. And you shouldn’t be whining about the heat if you’re having fun ya pussy.

My brother used to drive for a company delivering that sheet steel, and once his load shifted enough for it to cut through one of his cargo straps on the flatbed trailer behind him. Whereupon, a sheet went sliding off the trailer in this industrial park he was slowly rolling through, and got up enough momentum to slice cleanly through a telephone pole.

After thinking about what might easily have happened if there’d been any other cars around him that day, he quit that job and started hauling containers instead. Seemed safer all the way around.

Steel coils like that are unfortunately common things to fall off of trucks.

Herr-Voss or Bradbury? If it will go up to 1/2″, probably only will go down to 3/16-1/4″. I’m guessing 5″ diameter work rolls, 9 over 10 (or vice versa), double stacked back up rolls plus the adjustment rolls.

For the last 20 years, we have removed, installed or repaired CTL lines, slitters, roll formers and any other related equipment. Hard, dirty work and mostly you’re working on the floor. I’m same age as you and am in the process of retiring. Too old for it anymore.

Bradbury.

I think it will go down to 12 gauge.

Also. If you think those conventional levelers are greasy, heavy and nasty, try one of these.

https://redbudindustries.com/stretcher-levelers/

In the late ’70s, back in the days when sawmills existed in the Sierra, I spent a few winters hauling lumber. The hauls paid PUC rates and were pretty fair. When hauling to the L.A. area a guy could get a back haul of rolled steel from Fontana, I think it was, to the Campbell soup plant in Sacramento. But being a backhaul it only paid about half of what the trip south paid, so I never did it. I’d just shag ass back to the mill for another load of lumber rather than wasting a half a day waiting to get loaded and unloaded for a haul that was a rip-off anyway, hauling something tricky like rolled steel.

Add in the fact that when I went to L.A. all I wanted to do was get out of there and head back up to the NorCal mountains as quickly as possible. I’m funny that way.

Drivers call them suicide rolls. A sudden stop and the cab gets squashed like a cockroach under a steamroller.

Seen a few of those. Awesome raw power. As a buyer I bought millions of pounds of slit master coil. Similar except the cutting arbor made ribbons at whatever width the full length of coil and was rewound. Stampers buy a lot of it as well

I got the story chatting with Cederq, but thanks for the insight into the making of a curmudgeon. How do you shower that gunk off? Go-jo? Lava? Mil-spec degreaser?

Whenever coworkers would piss and moan about how hard their jobs were, my buddy and I would look at each other and roll our eyes. He started out on a dairy farm in north Idaho and moved from there to a sawmill pulling greenchain. I have not so fond memories of concrete work with a November drizzle draining down my neck, and roofing in August, where if you set a tool down, you’d better have a glove on to pick it up. With our indoor, AC job wearing white lab coats, all we could say was “I tried real work and didn’t like it much.”

I’ve been off grid for ten days (not mentioned earlier, OPSEC and all) helping my son frame up a cabin in the boondocks, so I’m just beginning to catch up on the ‘puter. Did I miss anything? I can say that at my age, I’m not much good for full time framing anymore. But I let the younger guys do the heavy stuff, and I reverted to being a pretty good gofur.

I wish I only had to take a piss three times a day. —ken

I got familiar with the Kaiser Aluminum rolling mill here in the Spokane Valley. While they don’t have a patch on rolling steel, it’s still awesome to watch a huge slab of still warm aluminum slab rolled into aluminum sheets darn near a mile long… The cooling loops were neat, they went down 150′ into the earth and back up again, only to be rolled again and go into another cooling pit.

Jerry Long, the head Electrical Engineer used to take us Scouts on a “behind the scene” tour of the more esoteric parts of the mill. Still cool to this day. Lots of “electrical vaults” where some mighty big-assed contactors were arcing and sparking – the ozone levels in those vaults was choking!

One of these days I want to do a similar tour of a hot or cold rolling steel mill. Already intimately familiar with wood product mills including plywood mills, seeing’s how I used to design the controls…

I’m glad I’m nowhere near there. When it’s back together, some bastard like me is going to have to calibrate all the measurement indicators on that thing; length, width, thickness, etc.

In the late 80s I worked as a maintenance mech in the USS-POSCO cold rolling mill in CA. Open shop, coils coming in by truck and boat. One of the dirtiest jobs I ever worked. I had a great time there, well paid, good crew. Built some serious industrial skills during that gig. The only problem I had was that it was in CA. I was really glad to move back to AZ.

Be very careful, Sir. Not to sound like Dudley Do Right but heat can fog the brain, cloud the judgement, foul the reflexes, etc. As a former long-term safety team member I would implore you to stay extra sharp under these circumstances. I’m sure you know what you’re working with is utterly unforgiving and a nanosecond’s mis-step can have dire consequences. Take due care.

It’s amazing the number of experts on pretty much any subject read and comment on this blog.

Yep