For the new and uninitiated, *STBD is an acronym for a phrase I coined a couple of years ago when I had THE BRONCO FROM HELL.

I have used it since, basically it covers Red Neck Repairs that you run into by some complete retard that either doesn’t know what he is doing or tried to fix something on the cheap.

This episode is one for the books, I’m tellin’ ya.

There is a once very nice and very expensive drill press at work.

Expensive as in well over a couple of Grand when new, a Clausing Variable Speed Drill Press.

As is what seems to be typical of old industrial equipment, this thing has seen better days.

I use it occasionally, first I had to clean the nasty thing up as it has downright been abused.

One of the things I noticed when I was cleaning it up, is one of the most Bone Headed, Stupid As A Box Of Rusty Hammers, cases of SHIT THAT BUBBA DID that comes to mind in recent memory.

For anyone not familiar with these machines, you can change the chuck on them by knocking a small arbor shaft out of the hollow drill post quill with a small wedge and a hammer.

If you have never seen or done that, watch about the first minute and a half of this video and you will see exactly what is going on there.

The inside of the quill has a slight taper machined in it and the arbor also has a taper. It is a Morse #2 Taper.

Basically when you shove the male arbor into the female quill, the two tapers will meet and create an interference fit.

These work great for up and down or back and forth shafts that spin.

They don’t work worth a damn for spinning side loads however.

This is why Milling Machines have a way to hold the tapers in mechanically, usually with a threaded rod that screws into the end of the taper.

This brings me to The Shit That Bubba Did on this drill press.

Drill presses do not have a way to run a threaded rod down the quill.

Therefore, drill presses are not meant to be used as a milling machine. The side load knocks the arbor loose and it drops out onto the work piece, spinning at rather high speed.

Bad things happen at that point.

So as I am looking at this drill press, I noticed something looked funny.

As I got in close I found this,

That Semi- Keyhole indentation there is supposed to be where you stick the wedge in to knock the arbor and drill chuck out at.

Some complete Jackass, welded the arbor to the quill.

On both sides!

This kind of thing is what gets people fired.

On the spot.

It’s also a damn good way to get a busted lip if I ever find you doing it.

You have just ruined a precision machined part on a piece of machinery that costs a couple thousand dollars.

Mad?

I was dumbfounded that someone could be that ignorant.

After I walked away for a few minutes to cool off, it occurred to me that the most obvious reason for this is that some complete dumbass was trying to use this drill press as a mill, the arbor and chuck kept vibrating out and they decided to cure that problem permanently by welding it in.

Permanently being a relative term in this case.

Enter Bustednuckles and one of his little friends.

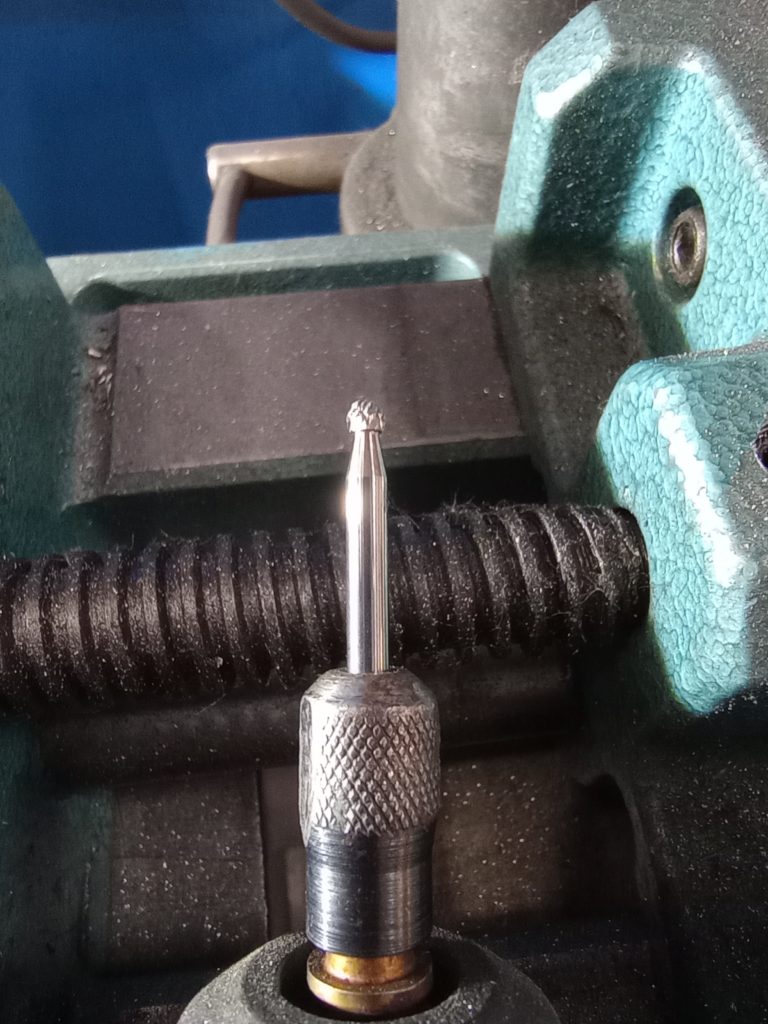

Lots of light, a good place to rest my arm to keep it steady, a Dremel with a tiny burr bit, face shield, gloves and LOTS of patience.

BOTH SIDES!

I got a real good feeling of playing Dentist.

After I pretty much got the keyhole shape dug back out, I went in with the heavy equipment.

You can’t really see it very good in that picture but at the very bottom of the bigger hole on top, is the top of the arbor that needs to be driven out with a wedge.

Of course I didn’t have one.

I have about 15 of them out in the garage though.

I ran out of time to try much of anything else but I figure I have a real good shot at getting that thing out on Monday.

When, not if, I get that bastard out of there, I also have a Morse Taper #2 Reamer out in the garage I am going to take in with me to clean that inner taper back up properly.

Then I am going to order a new arbor, with a brand new keyless chuck on it to put back in it.

I’m telling ya, no jury of my peers….

Surely there was someone in the area that knew better?

Looked to me like it had been that way for many years.

Yeah, married to a Dremel … no fun. But sometimes ya gotta do what you gotta do (we assume you have the flex/rotary shaft/hanging moto Dremel?).

It all takes me back to when I had my first scooter, at fifteen (two cylinder, two stroke Yamabanger 350).

And would sit with wrench in hand, while studying the factory repair manual. Under a naked incandescent 100w bulb.

Ah youth …

Well, I’m no machinist, I’m an Electronics/Computer/Electrical/Mechanical type of guy, with plumbing-framing-roofing-JOATMON stuff thrown in.

Even I know that a bloody DRILL PRESS is not a mill!

I never knew how to remove the chuck, but then, I never had a reason to do so.

Some people are just natural ‘tards and should never be left alone around machinery, moving or not. Just like some people should never be left unattended around about half the stuff I’ve worked on. Bad (in some cases, really bad!) stuff can happen.

Fools are protected by more capable fools. Most of us here are in the “more capable” category, although the jury is out on me…

Can’t fix Stoopid, all you can do is isolate ’em.

yup. that right there is some bastard shit work. back when the machine shops where closing down all over the place. a lot of very well made machine tools got sold on the cheap to assholes who had no idea what they where doing with them.

years ago, bought a south bend lathe for 50-100 bucks. for parts.

the bed looked like they used it as a pounding surface or something ?

the tailstock was gone. but the quick change gear box was like new.

headstock threads where in sad shape. so, saved the gear box, shims. and all of the bolts that where in good shape. the rest went to the scrap yard.

made money on the parts to pay off the expense of it. and got some spare shims

and bolts for my own lathe. but. I seen a few messes in my time.

and some really nice items in the scrap yard too. stuff way to big for home use

unless you need a 12 inch rotary table or a 12 inch surface grinder

I told my buddy I wanted to pick up a metal shaper. he called one day, they had one in the yard, I ran down with some tools and stuff to check it out

24 inch stroke, 2 ton monster shaper. had all the tooling too, vise jaws, 2 piece ones. a arbor stand of some kind. and a rotary table I couldn’t lift a inch !

I forget how big the motor was , but it looked like a small 55 gallon barrel in size

3 phase of course. I did grab a few of the tool bits, some 1/2 inch and a few 3/4

inch square tool steel is always nice to have. but those days are long gone now

the drill press I have is a old Walker-Turner one, 5 speed. slotted table that cranks up or down. close to 4-500 pound of it. mine takes a number 3 Morse taper. and yes, I know how to remove the chuck. I do so at time to use a Morse taper drill bits from time to time when I need to make a big hole, like over a inch.

I have a lot of big old drill bits like that. takes a while to sharpen them too.

and Phil, after you get the tang and socket right. change out that stupid bolt that

some asshole used instead of making a handle. anytime I see work like that, the price goes down a lot.

I would be that asshole that put the bolt in there, that handle is missing.

You can still get parts for these things but it requires calling them and I ain’t the parts purchaser.

I could make one using one of my lathes but after I get the quill fixed up I will have our purchasing agent call them and get one.

Ain’t got the time to fuck with that on my own dime.

so some asshole at work did this shit ??

to company tools ? what on a weekend when no one else

was around like ? most of the guys I worked for in the past

if they saw you doing some shit like that,, your ass be gone

in a flash. another thing, why is it some assholes like to take

handles ? I know why guys who take the gear change charts

off of lathe- to keep their job like, but handles ?

What a friggen douche bucket! Too bad you will never knew who did that! I would come up and kick his sorry little faggot ass all over Washougal! Mother Fucker would see the errors of his ways. Shit like that PISSES me off!

Ohio has stupid humans like that too. You’re a good fella for fixin that.

OG

should be able to pick up used air-driven dental handpieces (watch the obits) on the cheap; using carbides and diamonds I can “brush” the metal away, rather than drilling it – and with a water spray (goggles and a plandemic mask please) generated heat is minimal

Most excellent!

-rightwingterrorist

I used to have the old moto tool 280, the work horse of the dremel line.

used it for years doing all sorts of jobs with. everything from cleaning up valve seats and matching gaskets to intakes. to putting a fine shine on SU carbs.

and then it died. and the only ones they sold anymore where the speed controlled

ones. not half the ump of the old ones had.

some things do not get better with time.

I still have my model 280, going strong. Used it yesterday, sharpening a chain saw. I bought it sometime in the mid 1960’s as a kid doing model airplanes, and then got a separate speed control box that plugs inline. Almost never use full speed (30k rpm is a bit much). It’s a bit clunky to use, but I never have tried the built-in models. I’ll take your word for it that they’re not the same.

I remember the speed control box. I know I bought one, but

I be damn if I know what happen to it.

it was handy for inletting gunstocks and jobs like that

but for most job with a buffing or grinding wheel, I just used

it without the box. after moving a few times with sam, it got lost somewhere along the way.

I would vote to acquit.

I was the engineer in charge of the Model Shop at work. I was designing all the fixturing for the plant and TPTB decided that getting it built right was the way to go. I was given a budget to buy some equipment. Went to the used machine tool dealer and got a lathe to replace the belt drive Southbend 10 and a mill (Gorton) to replace the 1948 1J. I bought one new piece of kit and that was the Variable speed Clausing drill press. $2500 for it. It was beautiful in a way that only true metal geeks could understand. My office was up a flight of stairs from the shop.

One day I can feel somebody drilling into a nice piece of high graphite cast iron. I immediately run down to the shop floor and see the Stepson of the business owner (he was the “plant manager”) drilling through his work piece and into the table. I’m screaming at him to stop drilling and that he is putting the first hole in the table. He turns to me and calmly tells me that he owns the drill press to shut the “F” up. He continues to drill until he goes all the way through. The MoFo.

Two weeks later I’m no longer in charge of the Model Shop but am promoted and given an $8000 raise. BTW I could run all the tools in the Model Shop (thanks Dad). The replacement lathe and the mill were chewed to pieces by the 3rd replacement Model Shop manager and he got to buy new tools. He chose Chineseum Jet units which lasted 2 years. They are on the 5th one now and he knows his crap and has lasted 12 years now.