No need to snicker, I laugh at myself all the time.

I gotta say that even though this is Basic Machining 101 and the kind of stuff rookies get assigned to do in the real world, I am still so proud of myself that I could split.

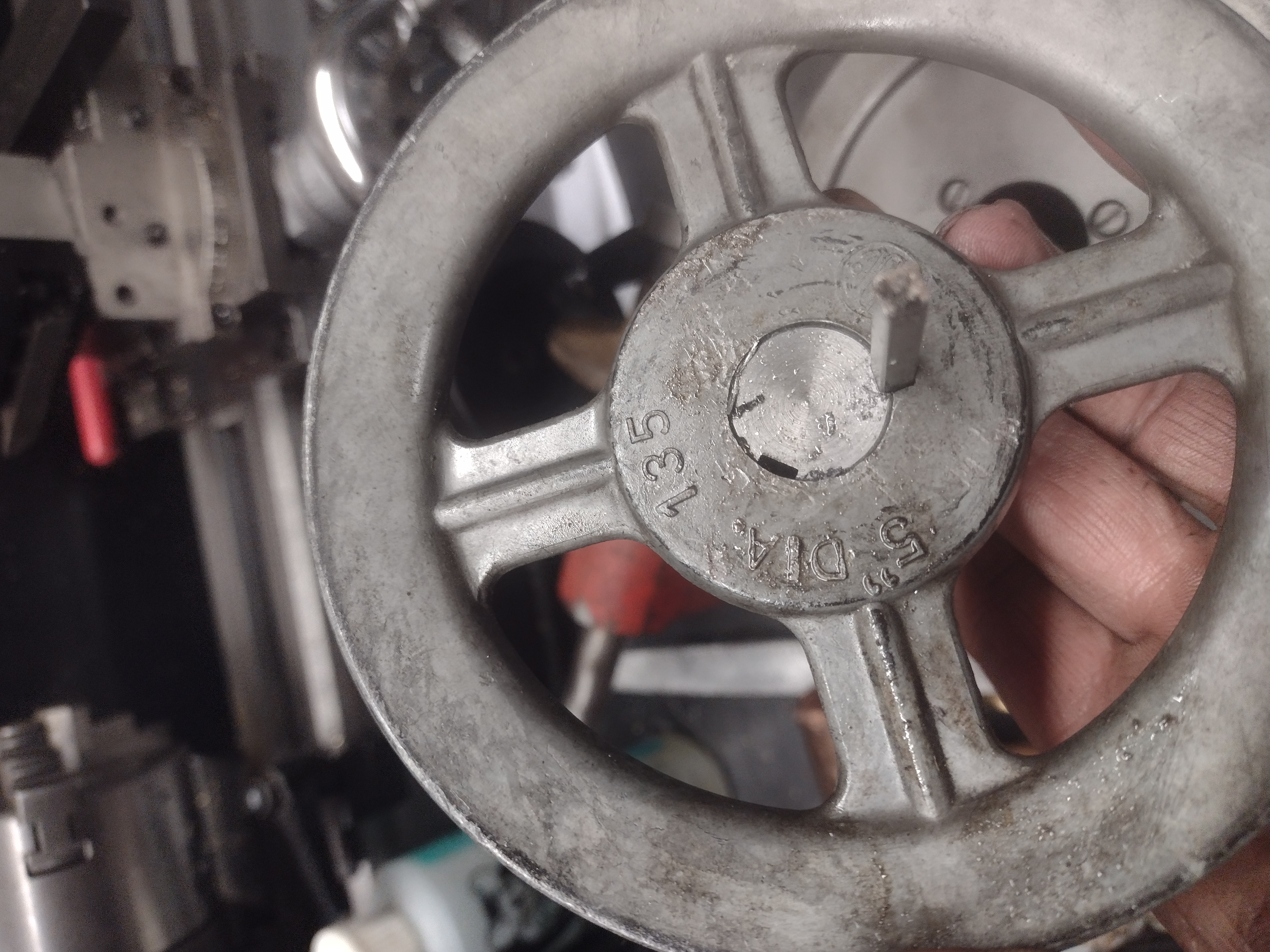

My first successful keyway using the old Smithy 3 in 1 machine.

I say successful because of course I had to screw one up first.

My blind old ass used the wrong sized cutter on the first attempt and I didn’t catch it until I went to test fit the key.

Ah well, live and learn eh?

I’m still pretty proud of myself. No adult supervision and I didn’t even break anything.

One down, one to go.

I’ve seen worse from people with a lot more experience. Well done, Sir.

Hell, I’m jealous of the opportunity………just started working with a mini-lathe, hope to buy a benchtop mill in the next year. Enjoy watching what your doing with that unit, and wish I could be that lucking to find something like it.

I’m a rank amateur but a helpful hint on cutting keyways is on the internet at Shaft Keyway Depth Calculator. Getting the spindle speed right and feeding the cross slide is my biggest challenge with my old Made in Taiwan mill. Having broken numerous endmills trying to get it right, I keep trying. I even bought a broach set to broach keyways in sheaves and bushings. Damn rewarding when it works and frustrating when it doesn’t.

Like a pro !

Glad to see that you had some downtime so you could play with your toys. Err, I mean tools. 😄

Awesome, Phil!

Reading about your machinist exploits makes me feel like a kid again. I never got as advanced as you are, even though I had the machine tools to do it. I just didn’t have the time back then to attempt to do what you are doing now.

Thanks for taking me along and making me feel young again, and please enjoy your accomplishments, even though you have to suffer through some frustrations in the process.

You’ve done a heckuva lot better than *I* could!

I haven’t even got my CNC working yet. Lazy me!